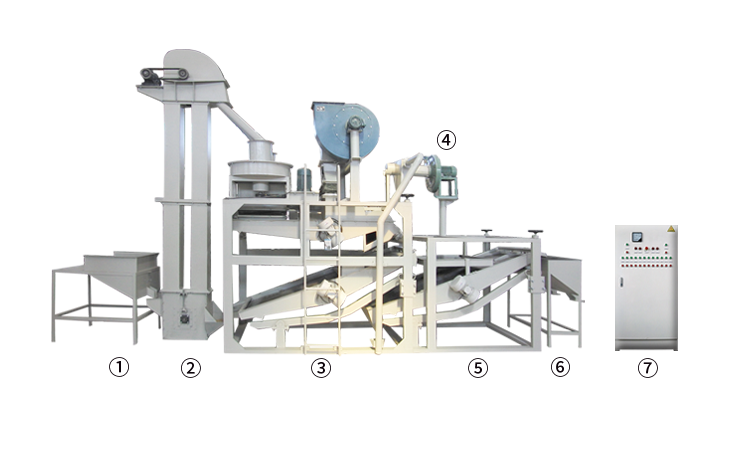

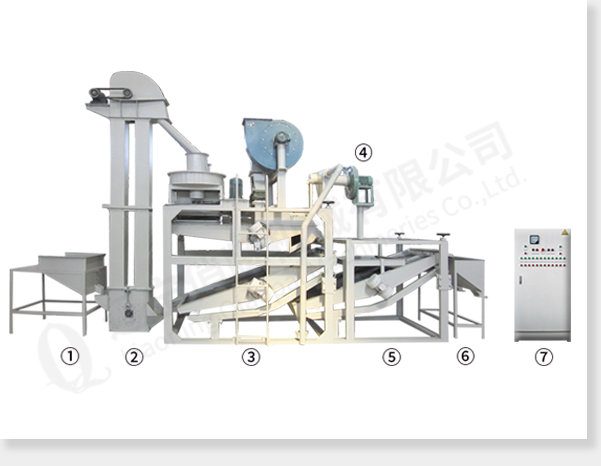

Oat Dehulling and Separating Equipment TFYM-1000

Component

① input hopper ② bucket elevator ③ main part of the equipment(dehullers,air separator and seed-kernel separator) ④ pneumatic system of back-flowing materials ⑤ seed-kernel reseparator ⑥ kernels bin ⑦ electric control cabinet

The equipment can complete the dehulling, shells-removing, seed-kernel separating of oats. It features low power consumption, compact structure, minimum space occupation, low loss of kernels, easy operation and maintenance, etc. In regard to its technical parameters, both the dehulling rate and percentage of whole kernel take the leading position in China, and it's the optimum equipment for oats primary processing.

Please slide to the right

|

TFYM-1000 |

Power |

Input Capacity |

% of Whole Kernel |

% of Inshell in Kernels |

% of Brokens in Shells | Overall Dimension (L*W*H) |

|

10.48-11.2kw(380v) |

0.8-1.0mt/h |

95%min. |

2%max. |

0.5%max. |

7.6×2.8×4.4m |

Demo video